How Forestry Professionals Choose the Right Tree Marking Paint

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

Click here to download this article in PDF.

What is the Biomass Industry?

The biomass industry produces renewable energy, biofuels, and other various bioproducts from organic material, such as plant or waste products. The term encompasses the production of biomass, such as wood pellet production, as well as the consumption of biomass, such as wood-burning industrial furnaces.

Biomass manufacturing equipment produces heat during the process of transforming organic materials.

Biomass equipment installed in exterior conditions may require a high temperature resistant, weather resistant, and corrosion inhibiting coating. Forrest Technical Coatings provides protective coatings that enhance the efficiency and longevity of biomass industry equipment.

In this article, we discuss high temperature coatings and our recommended products for the biomass sector.

What Are High Temperature Coatings?

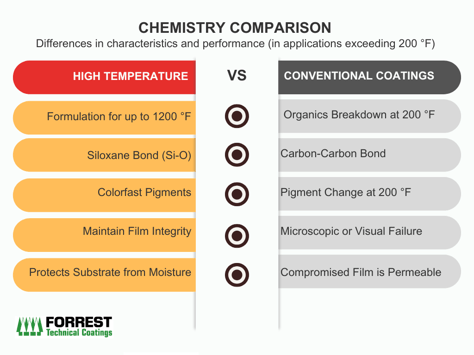

High temperature coatings are designed to withstand higher temperatures than conventional coatings. Components of conventional coatings may begin to fail visibly or at a microscopic level starting as low as 250 °F (121 °C). Silicone-based high temperature coatings are formulated with pigments, resins, and other components to withstand up to 1200 °F (649 °C) depending on the formulation. These coatings do not degrade under high temperature conditions and ensure a long-lasting film that protects equipment from corrosion.

In the biomass industry, where processing equipment is subjected to extreme temperatures in exterior environments, robust protection with a high-temperature coating can protect against corrosion and extend the equipment's lifespan.

How Are High Temperature Coatings Used in the Biomass Industry?

High temperature applications in the biomass industry include:

High temperature applications in the biomass industry include:

1. Pellet Manufacturing: Pellet manufacturing stands as a prominent component of the biomass industry, involving the compression of organic materials like wood chips into dense pellets for energy production.

2. Landfill Flares: Employed in waste management, landfill flares combust landfill gas (LFG) to reduce greenhouse gas emissions and control odors.

3. Biomass-Fired Furnaces for Wood Chip Drying: Integral to the wood chip drying process, biomass-fired furnaces require coatings that withstand extreme temperatures and exterior environments.

4. Regenerative Thermal Oxidizers (RTOs) and Catalytic Oxidizers: RTOs and catalytic oxidizers are both used to control the emissions of Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPS).

What Products Does FORREST offer to Manufacturers in the Biomass Industry?

54H Series: A silicone epoxy co-polymer high-temperature primer designed to provide excellent corrosion resistance in ambient or high-temperature conditions up to 1100 °F (593 °C).

62H Series: A modified silicon with rapid curing properties and good working properties over ferrous and non-ferrous metal surfaces up to 1100 °F (593 °C).

251H Series: Zinc-loaded formulations with excellent color and gloss retention, offering superior corrosion resistance on exterior surfaces, especially at temperatures up to 1100 °F (593 °C).

64E Series: A premium Acrylic Modified Alkyd Enamel with excellent color and gloss retention, tested for corrosion resistance up to a specified temperature range. Can be catalyzed for enhanced performance.

214E Series: A versatile and quick-dry low-HAPS, low-VOC high-gloss finish designed for interior or exterior exposure, providing corrosion protection when used over an industrial primer.

216P Series: Offering primer and topcoat solutions for different temperature ranges, ensuring protection and performance in various applications within the biomass industry.

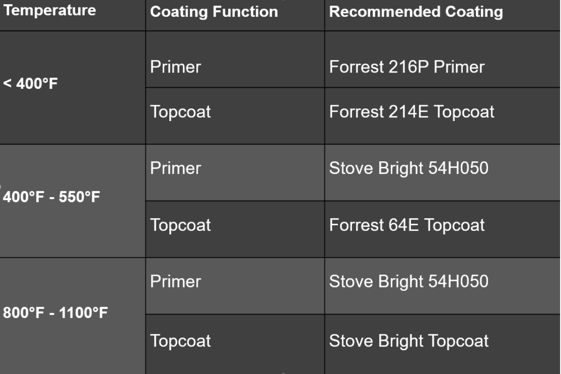

Suggested Coating Systems By Temperature Range:

Low-Range High Temp Coatings:

Medium-Range High Temp Coatings:

High-Range High Temp Coatings:

Questions about High Temperature Coatings?

Get in touch with FORREST Technical Coatings to ask about how our high temperature coatings can work for you.

FORREST Technical Coatings is a global supplier of conventional and specialty coatings including high temperature coatings, ESD coatings, and more. Notable brands include Stove Bright High Temperature Paint and INFERNEX Extreme Temperature Coatings. FORREST is based in Eugene, Oregon and serves manufacturers and consumers worldwide with high quality liquid coatings and powder coatings. Visit www.forrestpaint.com for more information or write to us at info@forrestpaint.com.

Ready to find the right coating for you?

speak to a Coatings expert 1-800-537-7201

Copyright © Forrest Technical Coatings. All Rights Reserved

Site Created by Cayenne Creative