How Forestry Professionals Choose the Right Tree Marking Paint

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

This article provides an overview of high temperature coating technologies available for operating temperatures from 200 °F - 1200 °F (93 °C - 649 °C)

High temperature coatings play a crucial role in safeguarding substrates from corrosion while operating at high temperatures. High heat rated components preserve coating integrity during extended operation while special additives provide resistance to environmental factors such as cold shock during operation, moisture, and UV exposure.

Use this quick reference guide for high temperature coatings to understand characteristics, applications, and key considerations for selection. Contact Forrest Technical Coatings, a leading global supplier of high temperature coatings, for technical consult on high temp product selection.

Click here to download this article in PDF.

High temperature coatings are protective barriers formulated with components rated for high heat resistance.

High temperature coatings are protective barriers formulated with components rated for high heat resistance.

A high temperature coating will:

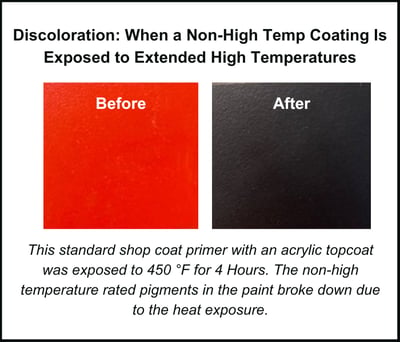

%20(1).png?width=400&height=343&name=rust%20example%20(700%20%C3%97%20600%20px)%20(1).png) In contrast, when a conventional coating is exposed to high temperatures, it may:

In contrast, when a conventional coating is exposed to high temperatures, it may:

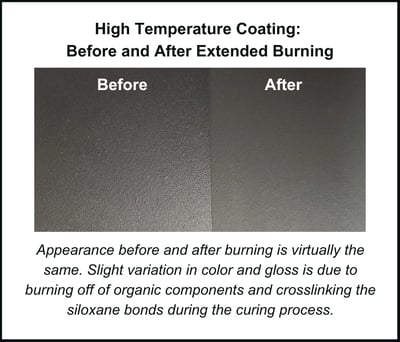

Silicone resins and robust pigments used in high temperature coatings remain stable even under extreme heat exposure. The coatings create a polymer casing around metal components to prevent direct contact between the substrate and moisture and other environmental elements.

The carbon-carbon bond found in most organic resin structures used in typical industrial paints is not strong enough to withstand heat exposure. The silicone resins used in high temperature paints are based on a silicone-oxygen bond (also known as siloxane bond or Si-O bond) that is about 25% stronger than the carbon-carbon bond. The siloxane bond forms a cross-linked structure during curing and ensures outstanding heat resistance, chemical resistance, and light degradation resistance. These factors increase the durability of the coating film and effectively prevent corrosion.

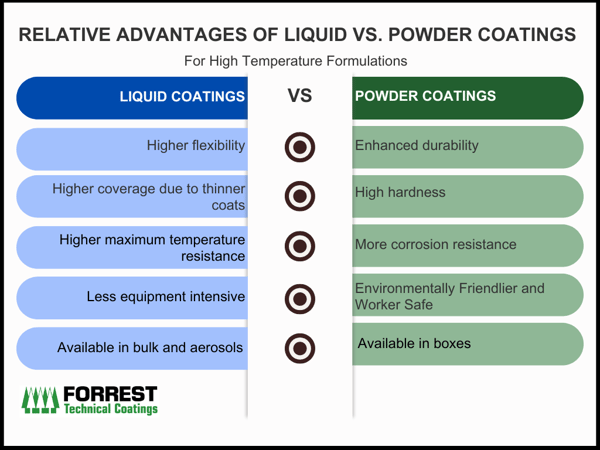

High temperature coatings are available in both liquid and powder formulations.

Liquid coatings are typically solvent-based and provided in bulk for sprayer application with aerosol touch-up availability as well.

Powder coatings are a solvent-free and environmentally-friendly option applied electrostatically and requiring specialized equipment.

In terms of performance, liquid high temperature coatings generally perform better in terms of flexibility, higher coverage due to thinner coats, and higher maximum temperature resistance.

Powder coatings offer advantages in durability, hardness, and corrosion resistance.

High temperature coatings are inherently high hardness and brittleness that can lead to failure. They are susceptible to integrity failure due to impact or sudden temperature fluctuations. Handling the product carefully during the curing process minimizes undesired fractures.

Chemists assess the performance characteristics of high temperature coatings using a range of adhesion tests, flexibility tests, durability and hardness tests, and, if necessary for the intended application, a quench test where the heated coating is rapidly cooled in cool or cold water. These tests provide accurate information to customers regarding the coating's performance in their specific application. The collaboration between specifying engineers or manufacturers and coatings chemists is crucial in selecting a product that strikes the right balance of performance characteristics for the intended end use.

High temperature coatings have a temperature maximum of around 1200 °F (649 °C) because metal substrates themselves begin to warp or degrade at these temperatures. Warped substrates compromise coating adherence. Stainless steel or ceramic coatings become the preferred option above these temperatures.

As a specialty high temperature coatings manufacturer, FORREST helps customers choose a coating to fit their particular temperature, application, and performance needs. Contact FORREST for technical consultation on choosing a coating.

Some specialty options available in high temperature coatings systems include:

Some specialty options available in high temperature coatings systems include:

Regardless of specific characteristics, high temperature coatings tend to have excellent exterior durability and light fastness and provide a range of aesthetic options.

What industries and applications use high temperature coatings?

%20(1).png?width=400&height=343&name=High%20temp%20barbeque%20coatings%20(700%20x%20600)%20(1).png)

High temperature coatings are often used in the following applications. Each industry requires a special high temperature coating that fits their specific application and performance needs.

High temperature coatings are available in standard and custom formulations and are uniquely suited to specific temperature ranges, performance needs, and application methods.

.png?width=400&height=343&name=Common%20Coating%20Failures%20(1).png) Information to aid coating selection:

Information to aid coating selection:

.png?width=400&height=343&name=substrate%20testing%20(1).png)

Technical sales and chemists work with customers to select appropriate coatings and work through testing with the customer. Your coatings team will work with you to collect the necessary information for selecting an appropriate coating. You will also work through a testing product to make sure the coating works for your application.

FORREST Technical Coatings is a global supplier of high temperature coatings known for the brands Stove Bright High Temperature Paint and INFERNEX Extreme Temperature Coatings. FORREST is based in Eugene, Oregon and serves manufacturers and consumers worldwide with high quality high temperature paint and powder coatings. Visit www.forrestpaint.com for more information or write to us at info@forrestpaint.com.

Ready to find the right coating for you?

speak to a Coatings expert 1-800-537-7201

Copyright © Forrest Technical Coatings. All Rights Reserved

Site Created by Cayenne Creative