How Forestry Professionals Choose the Right Tree Marking Paint

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

This Section Covers Resources

Revolutionizing Forestry Management with HIGHBALL® Tree Marking Paint's One-Pass Marking System

When metal components face sustained or cyclic heat, the choice of coating can determine how long they last before corrosion,...

Coating failures on exhaust systems, silencers, and other heat-exposed steel components are more than a cosmetic issue. They can shorten...

Cleaning your substrate to be painted is essential for success. Follow the tips below to ensure a successful project or download our Stove Bright® High Temperature Paint user guide to have all the information on hand as you complete your project.

Yes, all rust should be removed from metal surfaces. Surface contaminants affect the adhesion of high temperature paint. If not removed, the coating will adhere to the rust instead of the surface. A wire brush is effective for removing rust or in extreme cases sandblasting. If the stove already has a coating that is peeling, blistering, or chalking, or has any contaminant such as grease, oil, or dirt, then the paint will not adhere to the metal and fail.

For surfaces already painted with Stove Bright® or a compatible high temperature paint use 180 grit sandpaper or a medium-coarse plastic paint pad to provide a profile for the new paint.

For oil, grease, graphite, or other hard to remove contaminants, use lacquer thinner, toluene, or acetone. Do not use paint thinner or mineral spirits as these products leave residue. Please be aware of the HIGHLY FLAMMABLE nature of these products and the presence of harmful vapors. Eliminate all sources of sparks including household appliances and pilot lights and ensure you follow product instructions for personal protective equipment. Area should be well-ventilated whenever these products are used.

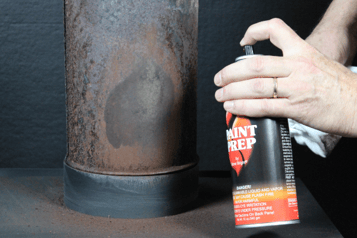

Stove Bright® Paint Prep in aerosol removes greasy fingerprints, light dirt and dust, and provides a final clean before applying the high temperature paint.

Do NOT use products like Formula 409 or a “tack cloth” sold in many paint stores. These products leave a residue that inhibits the adhesion qualities of Stove Bright® High Temperature Paint.

In normal indoor conditions, Stove Bright® is self-priming. A heat resistant primer may be necessary for extremely high humidity or outdoor use. In these cases, please choose a high heat primer designed to meet high temperature demands, as a regular metal primer will flake and peel when heated and give off noxious fumes.

Clean the surface with a wire brush that will free any deposits that have settled in the crevices and pores in the brick or masonry. Vacuum the brick and the floor of the fireplace to prevent loose dust from settling on freshly painted surfaces during application. If water was used in cleaning, wait 3 days before application to allow any moisture to evaporate. Similarly, wait 30 days before painting the surface of any new masonry, cement, or brick to allow it time to cure. Lightly brush the surface of new masonry and vacuum any loose debris before using the high temperature paint.

Still Have Questions About Preparation or Using Stove Bright® On your Project?

Ready to find the right coating for you?

speak to a Coatings expert 1-800-537-7201

Copyright © Forrest Technical Coatings. All Rights Reserved

Site Created by Cayenne Creative